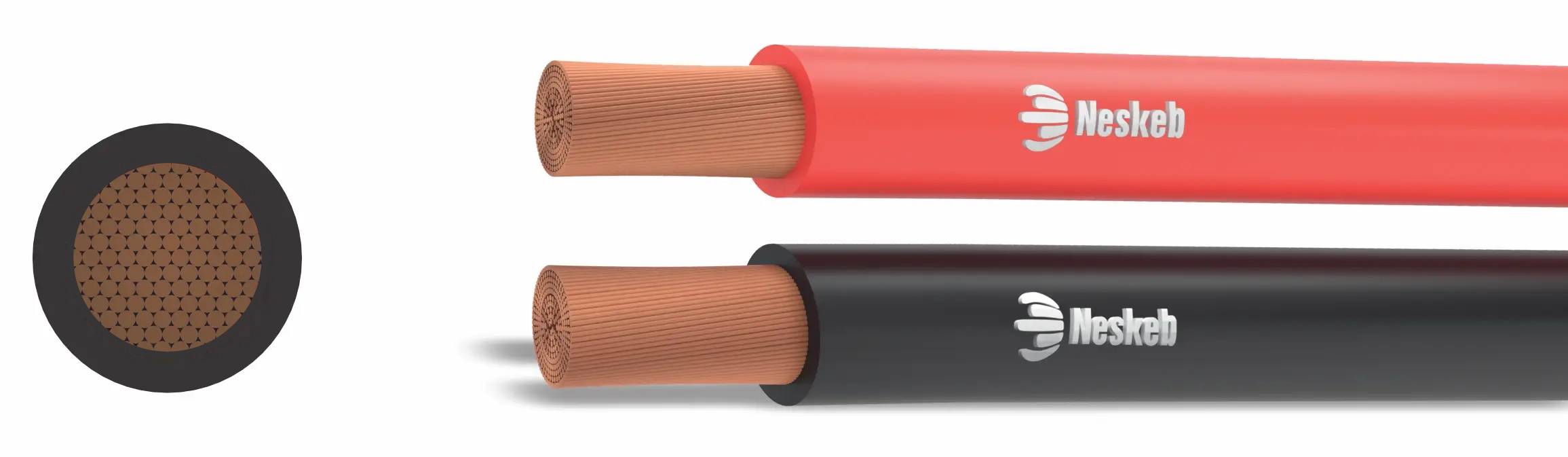

Battery Cables

Cable Standard

SAE J1127 VDE 0295, IEC 60228, IS 2465, BS 6862

Cables Features

- Excellent flexibility

- The NESKEB Auto cables is impervious to water, petrol, diesel, acids, engine and lubricating oils and grease resistant

- High mechanical strength

- Excellent flame retardant properties

- Excellent mechanical & electrical properties

- Special heat resistant insulation

- Minimum bending radius

Application

These wires used low voltage circuit in automobiles such a Vehicles and Motor cycles. Where high flexibility is required.

Standard Packing

Coils 25, 50, 100, 200 And 500m.

Conductor : Flexible Battery Cables: Flexible bare copper class 5 conductors to IEC 60228Extra Flexible Battery CablesFlexible bare copper class 6 conductors to IEC 60228

Insulation : Flexible Battery Cables: HR PVC

Flexible Battery Cables: HOFR(TPR Rubber)

Separator : Polyester tape over conductor for HOFR insulated extra flexible battery cables

Temperature : 20°c to 105°c

Core Colour

Red, Black

Data Sheet| PVC Insulated BATTERY CABLES as per IS 2465 : 1984 | ||||

|---|---|---|---|---|

| Conductor | Cable Parameters | |||

| Cable Size | Number/Dia. Of Strands(Nom.)mm |

Resistance at 20°C (Max.)ohms/km |

Nominal Thickness of Insulation (Nom.) mm. |

Overall Diameter (Approx.) mm |

| 10 | 140/0.30 | 1.91 | 1.0 | 6.50 |

| 16 | 126/0.40 | 1.21 | 1.0 | 8.0 |

| 25 | 196/0.40 | 0.780 | 1.2 | 10.50 |

| 35 | 276/0.40 | 0.554 | 1.3 | 12.0 |

| s0 | 396/0.40 | 0.386 | 1.4 | 15.0 |

| 70 | 360/0.50 | 0.272 | 1.4 | 17.50 |

| 95 | 480/0.50 | 0.206 | 1.6 | 19.0 |

| 120 | 608/0.50 | 0.161 | 1.6 | 22.0 |

| 150 | 750/0.50 | 0.129 | 1.8 | 25.0 |

| 185 | 931/0.50 | 0.106 | 2.0 | 28.0 |

| 240 | 122/0.s0 | 0.0801 | 2.2 | 32.0 |